Ready Mix Concrete

Ready Mix Concrete Definition and summary here.

Performance Mixes:

| Mix | Common Uses |

|---|---|

| 3,000 & 3,500 psi | Footings, Flatwork, & Foundations |

| 4,000 psi | Footings, Slabs on Grade, Driveways, & Walls |

| 4,500 psi | Slabs on Grade, Driveway, & Walls |

| 5,000-10,000 psi | We can design any mix to meet your high strength specification |

We also carry the following specialty mixes:

| Mix | Description |

|---|---|

| Flowable Fill | Self-compacting low strength material with a flowable consistency that is used as an economical fill or backfill material as an alternative to compacted granular fill. |

| Grout | Grout is a construction material used to embed rebars in masonry walls, connect sections of pre-cast concrete, fill voids, and seal joints (like those between tiles). |

| SCC | Highly flowable, non-segregating concrete that can spread into place, fill the formwork and encapsulate the reinforcement without any mechanical consolidation. |

| High Strength | A type of performance concrete generally with a specified compressive strength of 6,000psi or greater. |

| Decorative | The use of concrete as not simply a utilitarian medium for construction but as an aesthetic enhancement to a structure, while still serving its function as an integral part of the building itself such as floors, walls, driveways and patios. |

| Lightweight | Lightweight concretes can either be lightweight aggregate concrete, foamed concrete or autoclaved aerated concrete (AAC). Such lightweight concrete blocks are often used in house construction. |

If you are interested in ordering, or if you have any questions, please contact the closest Location to you.

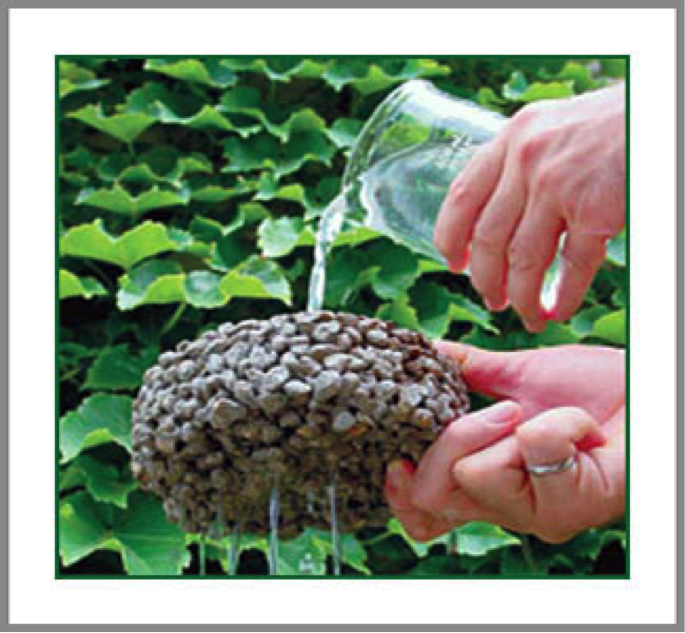

Pervious Concrete

Pervious concrete pavement is a unique and effective means to address important environmental issues and support green, sustainable growth. By capturing stormwater and allowing it to seep into the ground, porous concrete is instrumental in recharging groundwater, reducing stormwater runoff, and meeting U.S. Environmental Protection Agency (EPA) stormwater regulations. In fact, the use of pervious concrete is among the Best Management Practices (BMPs) recommended by the EPA—and by other agencies and geotechnical engineers across the country—for the management of stormwater runoff on a regional and local basis. This pavement technology creates more efficient land use by eliminating the need for retention ponds, swales, and other stormwater management devices. In doing so, pervious concrete has the ability to lower overall project costs on a first-cost basis.

In pervious concrete, carefully controlled amounts of water and cementitious materials are used to create a paste that forms a thick coating around aggregate particles. A pervious concrete mixture contains little or no sand, creating a substantial void content. Using sufficient paste to coat and bind the aggregate particles together creates a system of highly permeable, interconnected voids that drains quickly.

Both the low mortar content and high porosity also reduce strength compared to conventional concrete mixtures, but sufficient strength for many applications is readily achieved.

While pervious concrete can be used for a surprising number of applications, its primary use is in pavement. This site focuses on the pavement applications of the material, which also has been referred to as porous concrete, permeable concrete, no-fines concrete, gap-graded concrete, and enhanced-porosity concrete.

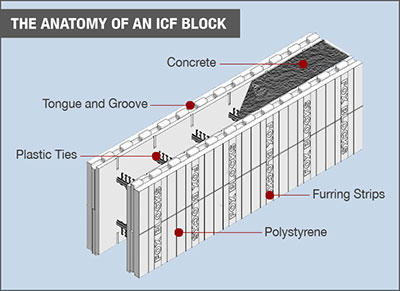

Insulated Concrete Forms

ICF decking is also becoming increasingly popular in addition to ICF wall construction. ICF decking weighs approximately 40% less than standard concrete flooring. It is commonly used in conjunction with ICF wall systems to form a monolithic structure with superior wall and floor insulation. Together ICF and concrete can contribute points in every LEED category. For more details, or product specific information, follow one of the links below. For purchasing inquiry, please contact brian@wellsgroup.net

Quality is Our Philosophy

The Wells Group LLC currently has four certified aggregate technicians working for the company. The philosophy of The Wells Group has always been to meet or exceed all quality expectations and specifications. We take every reasonable resource to achieve this end. We believe that our customers should not have any concerns about the quality being deficient or the supply of concrete being insufficient. Quality is the prime consideration of The Wells Group. We have a comprehensive quality assurance (QA) and quality control (QC) program. We have a civil engineer on staff that wrote the quality control program and oversees its implementation. The QA/QC program includes daily testing of the aggregates and fresh concrete, regular strength testing of the hardened concrete, and periodic quality assurance reports from suppliers. All of our plant scales are certified semi-annually. All of the concrete mixers are Kentucky Department of Transportation certified.

Our Affiliates

Decorative Concrete can be broken down into many categories. This is because it has more to do with how the concrete is placed and finished than it does with what we put into the truck.

Colored Concrete – Color can be put on the surface of concrete or incorporated into the mix. There are many colors to choose from, ranging in price drastically.

Stamping– Stamping the surface of concrete can give the look of cobblestone, brick, flagstone, there are many different shapes and patterns. These are usually incorporated with and integral color and a surface color/sealer.

Stenciling—This can also give you the look of stamping, but without as much texture. Stenciling is typically done with a “shake-on color” , that is floated in the surface after a stencil pattern has been placed over the leveled concrete.

Acid Etching– This is normally an inside application, where acids mixed with colors are placed on hardened concrete slab. These usually have a pattern already sawed into the surface.

Precast

We carry a wide variety of precast products, including the following:

| Septic Tanks |

|---|

| 1000 Gallon w/ riser |

| 1500 Gallon w/ riser |

| D-Box (8 hole) 15″W x 14″H x 29″L |

| D-Box Lid |

| Riser (6″) |

| Riser Lid |

| Retro Fit Riser |

| Filter |

| Flow Leveler (4″) |

| Man Hole Lid (24″) |

| D-Box Baffle |

| Septic Tank Baffle |

| 1000 Gal Lid |

| 1000 Gal Lid w/ Riser |

| 1500 Gal Lid |

| 1500 Gal Lid w/ Riser |

| Cisterns |

|---|

| 1000 Gallon 67″ x 97″ x 60.5″ |

| 1500 Gallon 67″ x 146″ x 60.5″ |

| Modified Tanks |

|---|

| 1000 Gallon 67″ x 97″ x 60.5″ |

| 1500 Gallon 67″ x 97″ x 60.5″ / 67″ x 48″ x 60.5″ |

| Stepping Stones |

|---|

| 24″ x 24″ Block |

| 24″ x 24″ Sunburst |

| 12″ x 12″ Square |

| 16″ x 16″ Hexagon |

| Planters |

|---|

| Normandy Jr. (10″ Sq. x 9″ H) |

| Normandy Sr. (28″ L x 13″W) |

| English Planter #1 (23″ Dia. x 18″ H) |

| English Planter #2 (36″ L x 11″ H) |

| English Planter #3 (18″ Dia. x 26″ H) |

| Misc. Concrete Products |

|---|

| 30″ Splash blocks |

| 7′ Paking curbs w/ pin holes & drains |

| Parking Curb Pins |

| Lovers Bench (5′ L x 18 “W x 21” H) |

| Picnic Table (85″ L x 31″ W x 32.5″ H) |

| 2’x2’x3′ Block |

| 2’x2’x6′ Block |

| Brick Ledge / Window Seal (24″) |

| Telephone Pads |

| Large Pallet (Refundable if returned) |

| Small Pallet (Refundable if returned) |

Used Equipment

We usually have used Equipment for sale. Please contact Steve Burton for information on what is available at 606-743-3485

Concrete Admixtures

We proudly supply the following concrete admixtures:

| Admixture | Description |

|---|---|

| Air Entrainment | Introduces microscopic bubbles into the concrete that act as stress pockets to combat freeze/thaw cycles and optimize durability. |

| Mid-Range Water Reducer | Increases workability and flowability of the mix while increasing strength |

| Superplasticizer | Facilitates the placing and finishing of ready-mixed concrete that is highly flowable and workable for extended periods of time with normal setting characteristics. |

| Retarder | Prolongs the workability and set time of plastic concrete. |

| Accelerator (Non-Chloride) | Speeds up the set time of concrete without damaging the steel. |

| Fiber | Helps reduce plastic shrinkage of concrete and increases flexural strength. |

Cure & Seals

WHAT IS CURE & SEAL?

Cure & Seals take the properties of both curing compounds and membrane forming sealers and combines them to yield the best performance properties of both. Where normal curing resins last only weeks before they wear off, some Cure & Seals will last up to to 5 years, depending on which product is applied. When applied correctly, Cure & Seals form a hard, shiny and durable surface that resists all waterborne contaminants and protects the concrete through its infancy and early life.

WHY CURE?

Concrete curing is the satisfactory maintenance of adequate moisture around and in newly placed concrete. Curing compound, applied immediately following placement, allows concrete to develop the necessary desired strength and durability. Concrete exposed to the elements is especially sensitive to improper curing because the strength development can be significantly reduced from excessive surface evaporation and exposure to freezing.

WHY SEAL?

Concrete sealers are used on concrete to close up the pores in the concrete surface so it will resist water, de-icing salts, and other aggressive chemicals. Sealers are often used to prevent soiling, resist staining, facilitate the ease of cleaning, brighten concrete colors and exposed aggregates, and produce a water resistant surface. Sealers may also be used to dustproof concrete surfaces. Superior quality sealers usually consist of pure forms of acrylic resin that are non-styrenated and non-yellowing. Quality concrete sealers will last three to five years and require minimal maintenance.

We proudly supply the following:

Cure & Seals:

Penetrating Sealers:

Other: